RUBBER / METAL ADHESION

The factor that most influences the ease of adhesion is the type of rubber base and its formulation.

Preparation of the metal:

Cleaning:

Chemistry: Use solvent (eg ethyl, methyl, ketone). Degreaser

Mechanics: Sanding, grinding: Elimination of rust and dry dirt.

Surface Preparation:

Sandblasting: Greater specific adhesion surface.

Final cleaning: Clean again.

RUBBER / RUBBER ADHESION

Preparation of surfaces

Use solvent to clean surfaces

Let evaporate

If joining ends, cut at 45 °.

Recommended adhesives:

To join rubber / silicone:

Selladores »Siloc», »Orbasil», etc.

To join other rubbers:

Pegadores instantáneos: »Loctite», »Ciano»,Cemento de contacto: 3M, etc.

Note: If these procedures are not performed or are not done properly, adhesion may fail. In all cases let dry / cure 24 hours.

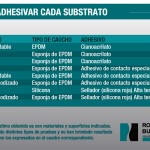

ADHESIVE A SUBSTRATE

Steps to follow:

1- Clean the substrate and the type of rubber to be used with liquid that does not deposit fatty residues such as, for example, isopropyl alcohol, trichlorethylene, methyl ethyl ketone, among others.

2- Sand the material and clean it again to remove the impurities.

3- Distribute the adhesive evenly on the 2 surfaces to be glued, in the case of contact adhesive

4- Allow a few minutes to breathe and then proceed to the paste in the case of the contact adhesive.

- Click to see the extended tables: